02

Quality Mianagement

QUALITY MIANAGEMENT

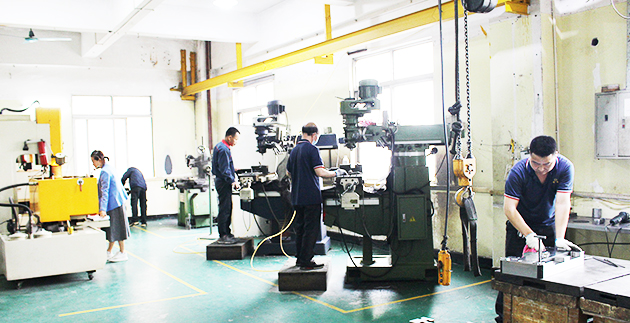

We implement a comprehensive quality management system that emphasizes both product quality and service quality, providing customers with excellent products and satisfactory services

Implement the quality management system and strictly control the production quality

Strict incoming and outgoing inspections ensure high-quality raw materials and excellent products

Quickly responding to customer feedback, a comprehensive process control system ensures stable and controlled product quality

High precision testing equipment that meets all testing requirements for aluminum/zinc alloy die-casting and die-casting molds