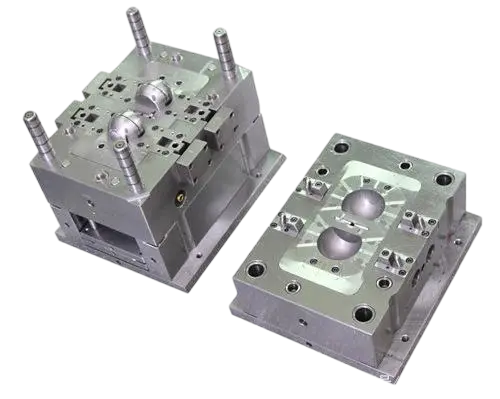

Die casting molds

Product Name:Die casting molds

1. Design: Based on the shape, size, and requirements of the product, design the mold cavity, core, pouring system, ejection mechanism, and other structures.

2. Material selection: Choose suitable mold materials based on the type and performance requirements of the die cast metal, such as high-strength alloy steel, heat-resistant steel, etc.

3. Processing: Advanced processing technologies such as CNC machining, electrical discharge machining, and wire cutting are used to accurately process various components of the mold.

4. Heat treatment: The mold is subjected to heat treatment processes such as quenching and tempering to improve its hardness, strength, and wear resistance.

5. Surface treatment: Improve the surface quality and corrosion resistance of the mold through surface treatment processes such as spraying and chrome plating.

6. Assembly and debugging: Assemble the processed mold components, debug and test them to ensure that the performance and quality of the mold meet the requirements.